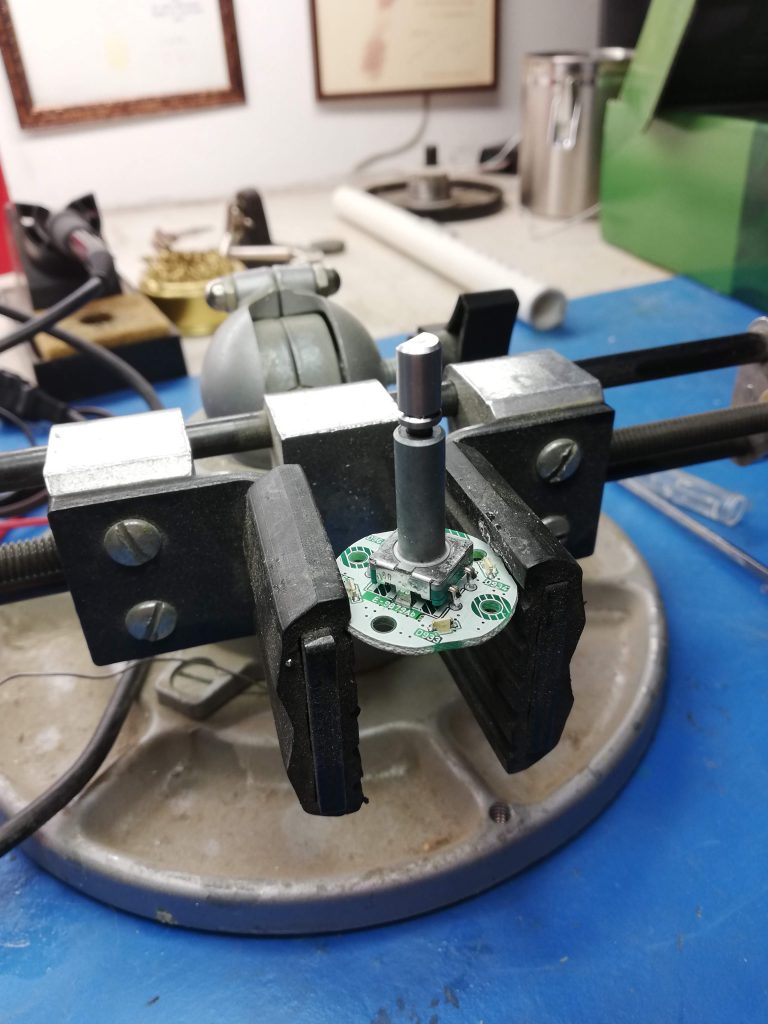

The volume knob in my wife’s Toyota Highlander behaved weirdly. As you turned it up or down, the volume setting would jump up or down, sometimes in the wrong direction and by an unpredictable amount. It didn’t give a linear output as you would expect. What to do? Why, take it apart of course!

Tag Archives: electronics

Cordifying battery things

In my house, we have a ton of “batteried” devices. Having small children, in this modern age, one tends to collect a lot of toys, tools, crafts, and associated appliances that require an array of batteries. Triple- and double-As are in high demand, though 9V and even the C cells are occasionally used. Don’t even get …

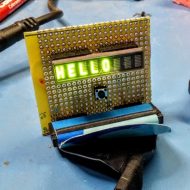

Day 30: final day

This post is part of the GaSiProMo challenge. You can read more about this here. I’ve got most of the bugs ironed out in my display interface, but not all have been squashed in the driver portion. In other words, the method in which I can input text into the OsRAM is working nicely …

GaSiProMo

I’m a notorious task-starter, and not a great task-finisher. My garage is littered with old projects that are collecting more dust than accolades. I can lean on the old, dependable excuses but really that’s lame. If every moment is the new normal, then there aren’t any excuses. Our hobbies define us, and I love my …

Inaugural Maker Faire

Well, I’ve officially joined the DIY electronics community. Last week, I attended my first Maker Faire. It was my city’s first ever, and I was determined to take one of my projects as a booth participant. Nothing like a deadline to get my hind quarters into gear and (kind of) finish a project!

The state of the Arduino ecosystem

*** The following is a “bitter old engineer” rant. You’ve been warned. At this ripe old age, I have come to value most the quality of a toolchain. I’ll go a step further and say that the coherency and consistency of the umbrella that toolchain inhabits is a most prized quality. And what spurred this revelation? …

Dell OptiPlex motherboard repair

My office was liquidating a bunch of old computer equipment. In the heap, my eye was caught by a Dell box. “Hmm, what’s wrong with that computer?” And so began my next big obsession.

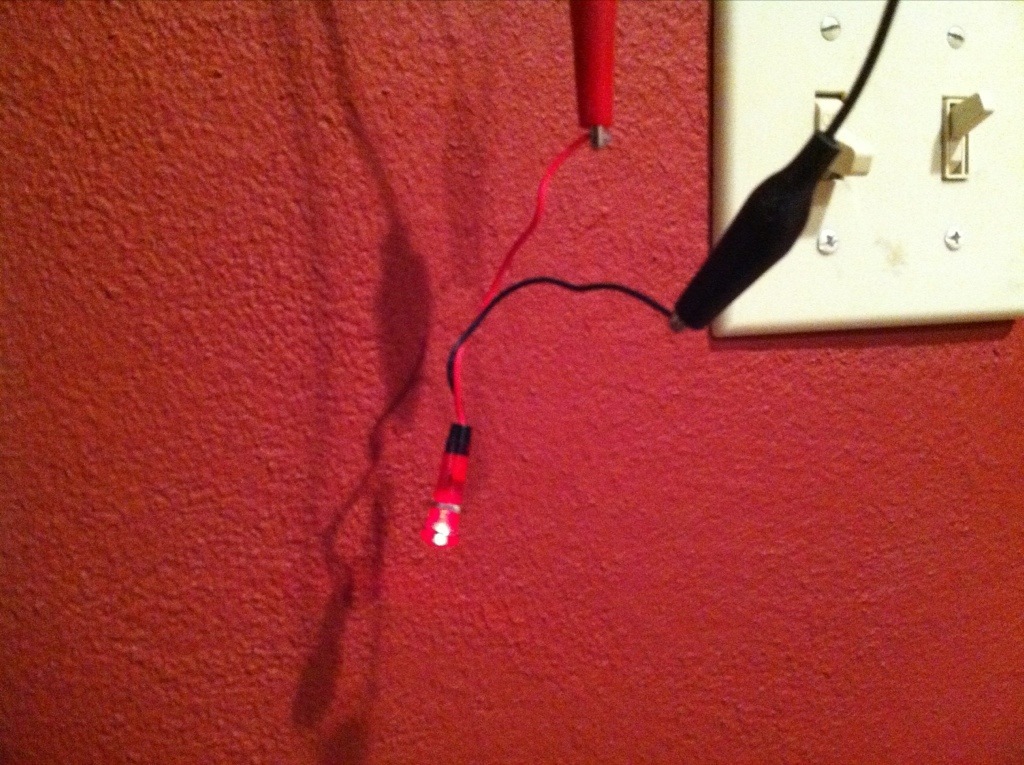

Sparked interests and water analogs

Today, on the way to visit friends, my daughter asked me probing questions about one of my favorite little obsessions: traffic signals.

Surround Sound Debug

For some reason, this keeps happening to me. I must be doing it wrong. But I’ve either been too stubborn or too distracted to find the better way to do it. I’ve installed surround sound wiring into my abodes at least five times (twice in my bachelor days at two different apartments , and thrice …

Cell phone connector fix

My good friend James contacted me with an electronics problem. Seems his daughter’s cell phone was on the fritz. So I agreed to take a look. She has a Pantech P7000 flip phone, but it stopped charging. I asked a few questions first to understand the nature of the problem. For instance: Has she tried …